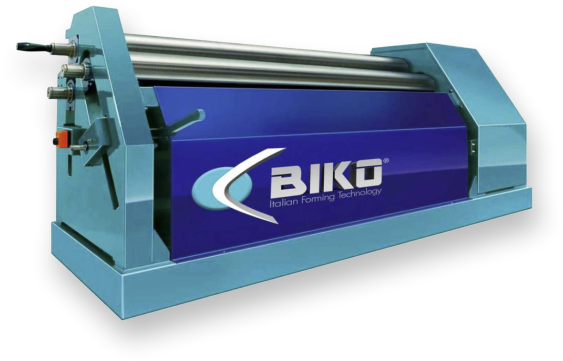

BIP - single 3-roll plate bending

Single Initial Pinch Plate Rolls

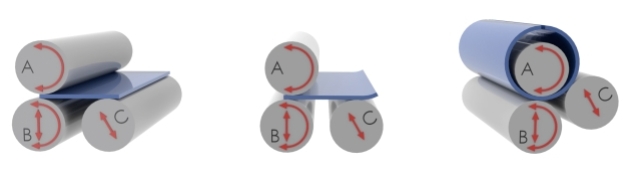

The BIP version of plate roll guarantees superior quality of bending thanks to the asymmetric geometry of the roll movement. Optimal plate drive is guaranteed by the two powered pinch rolls and is ideal for preventing any slipping even on very thin plate.

The side roll bends the material very near to the asymmetric clamping point resulting in a prebending quality superior to the one achievable with the more expensive 4 roll design. A convenient foot pedal control allows a one man operation for plate loading and prebending operations.

Rolling of profiles is possible as a result of the extended roll shafts, provided as standard on all models, so it is possible to mount either standard profiles of pipe dies. The BIP series of plate rolls is surely the most convenient way to roll your shells consistently with a minimum investment.

CONTACT US