B3 - 3-roll plate bending

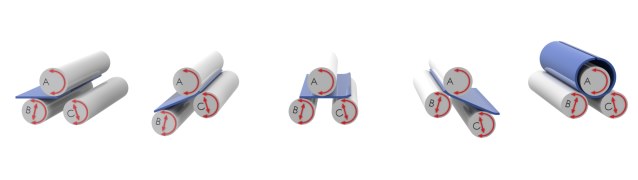

3-Roll Double Initial Pinch

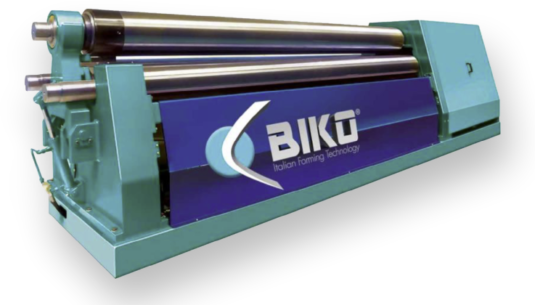

Capacities ranging from 1.5 metre to 3 metre and 3mm to 70mm.

The Biko B3 three roll double initial pinch bending roll machines, are manufactured with capacities ranging from 1.5m to 3m and 3mm to 70mm, and have been designed to achieve the most versatility in a traditional industry.

With all three rolls independently driven by independent motors and gearboxes, two powerful hydraulic cylinders to each roll and a hydraulically operated drop end bearing for the removal of completed cylinders, the machine has the capabilities to produce high quality rolled parts and as a result of its low competitive cost is the preferred machine of the general fabricator, who needs the assurance of a strong and user friendly machine. General fabricators are the main users of this product.

Within our range the Biko B3 offers the maximum rolling power with the minimum investment cost.

CONTACT US